Search published articles

Showing 2 results for Taromi

Majid Taromi, Maziar Hosseini, Seyed Mahdi Pourhashemi, Majid Sadeghi,

Volume 11, Issue 1 (Vol. 11, No. 1 Spring 2017 2017)

Volume 11, Issue 1 (Vol. 11, No. 1 Spring 2017 2017)

Abstract

./files/site1/files/3Extended_Abstract.pdfExtended Abstract

(Paper pages 51-72)

Introduction

Value engineering is considered an efficient alternative to improve design and construction process of urban tunneling projects. Application of value engineering techniques can provide investigating all aspects of a project in a team work, creative and short-time manner which contribute to precisely identify a project’s quality improvement issues, construction time and costs.

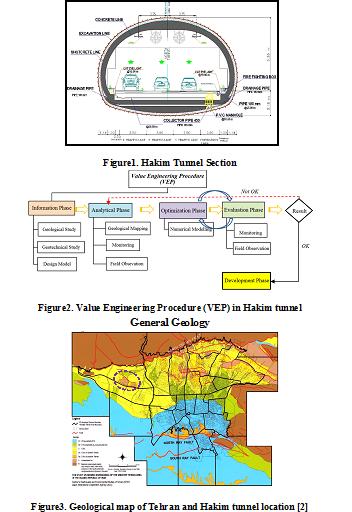

Hakim Expressway one of the capital's main highways in Tehran metropolis with 9 Km in length, starts from the junction of Resalat expressway and Kurdistan expressway after Resalat tunnel and ends in Lashgari expressway. The west extended this highway passing through the area of Chitgar forest park. Due to environmental constraints, the Hakim twin tunnels with cross-section of 186 m2 excavation areas and total length of 3256 m to the NATM/SEM method in this area were excavated (Figure 1).

In preliminary design of Hakim tunnel project, on category of excavation and support system was suggested. During the tunnel’s excavation operation, the behavior and classification of the tunnel were investigated from field observation, instrumentation and monitoring of geological models and subsequently, further excavation process was modified in accordance with value engineering. The aim of using value engineering approach in this project was to reduce the costs without any decrease in quality, employer satisfaction along with minimum risk and as well as improving operational and practical aspects. Ultimately, establishment of the value engineering approach on Hakim tunneling project leads to 10% reduction in construction costs as well as relevant quality with the least challenges (Figure 2).

General Geology

The city of Tehran is founded on Quaternary alluvium, which has been geologically classified by Rieben [1]. The city is located at the foot of the Alborz mountain range, which is basically composed of Eocene pyroclastic deposits (green tuff) and other volcanic rocks. The geology and the morphology of the Tehran region is similar to that for other cities located at the foot of mountains.

Rieben (1966) divided the Tehran coarse-grained alluvia into four categories, identified as A, B, C and D, where A is the oldest and D the youngest (Figure 3).

Hakim tunnel project locates on foothills of northern Tehran, crossing the hills of Chitgar forest park. Results of field surveys indicate that alluvial deposits in tunnel track belong to C (ramps and tunnel portal) and A formations (in most parts of tunnel track).

Geotechnical characterization

Table1 summarizes soil input parameters. Two soil types were considered for the model with 8- meter-height overburden. First layer (No.1) starts from surface with a 1 meter thickness. Second layer (No. 2) has 7 meter thickness.

Table1. Summary of the geotechnical parameters

| Parameter | Unit | Layer No. 1 | Layer No. 1 |

| Internal friction angle (CU) | Deg. | 29 | 33 |

| Cohesion (CU) | Kg/cm2 | 0.15 | 0.45 |

| Density | Kg/cm3 | 18.5 | 20 |

| Poisson ratio of unloading/reloading | Kg/cm2 | 0.2 | 0.2 |

| Secant deformation modulus | Kg/cm2 | 550 | 900 |

| Power of stress level of stiffness | 0.5 | 0.5 | |

| Stiffness unloading | Kg/cm2 | 1650 | 2700 |

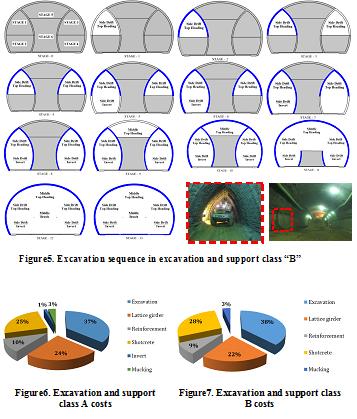

Detailed analysis before excavation and continuation of studies led to two excavation and support classes purposed for Hakim tunnel. Both classes of excavation and support due to ground conditions are modeled and analyzed using software Plaxis. For verification, the results of numerical analysis using monitoring and field observations were compared during the tunnel excavation. The results of monitoring compliance with the results of numerical analysis were appropriate.

Implementation and construction costs were calculated for different sections of two excavation and support classes in accordance to contraction documents to evaluate the effect of optimization in design (Figures 6, 7)

.jpg)

Figure4. Excavation sequence in excavation and support class “A”

Results

Results indicate that in both classes maximum costs are related to excavation section while minimum costs are for invert and mucking. In all concrete spray operations there was just a %3.5 increase in costs. Overall savings in excavation and support was about %10 which is significant (Figure 8).

Figure8. Savings percentage comparison in excavation and support classes A and B

Maziar Hosseini, Majid Taromi, Mahdi Saeidi, Vahid Soleimani, Mehdi Soltani Negar,

Volume 14, Issue 4 (12-2020)

Volume 14, Issue 4 (12-2020)

Abstract

Introduction

Series A of coarse-grained alluvial deposits of Tehran are extended in eastern and north-eastern areas of Tehran. Analyzing and studying of these alluvial deposits from a geological point of view as well as their creation time and general characteristics such as the deposits’ mineral types, their source, and formation conditions, gives a better point of view to geotechnical engineers about exploring their characteristics as well as geotechnical aspects in underground structure design, excavations, and foundation design processes. On the other hand, in order to analyze stability, estimating the factor of safety and the seismic design of these structures, considering their location, which is in Tehran with a high seismic hazard area, the necessity of knowing the exact mechanical and dynamic properties of Tehran's alluvium is felt more than ever.

Material and methods

Due to the grain size of Tehran’s coarse-grained alluviums (series A) as well as high level of cementation of them, it is impossible (or maybe so difficult) to make undisturbed samples in order to do experiments. Such that it is excavated 23 boreholes with 30 to 140 meters depth as well as 17 test wells with 20 meters depth in an area which was extended in 10 kilometers in long which were located in Tehran’s No. 13 and No. 14 districts (as it can be seen in Figure 1). During the excavation of the entrance ramp and tunnel of eastern highway of Tehran, in-situ tests have been done in different sequences. Since it was important to investigate real behavior of these alluviums, different in-situ tests such as plate load test, in-situ shear test, pressuremeter test, and downhole test have been done as well as many laboratory and field tests. Furthermore, (1) X-Ray Diffraction (XRD) and (2) X-ray Fluorescence (XRF) as well as (3) Scanning Electron Microscopy (SEM) methods, have been used to explore the type of minerals and those used in cementation.

(ب)

Figure 1. a) Geological plan and the location of boreholes and test wells in the alignment of East Tehran Freeway

Results and discussion

Based on the results of XRD tests, it is quite clear that the largest weight percentages of tested samples are lime and silica.

Calcium and magnesium levels-as the high-power cations in flocculation process-in soil sample No. 1 (soil with high cementation level) are much more than soil sample No. 2 (soil with moderate cementation level).

This is the cause of high cementation level of soil sample No. 1 comparing with soils sample No. 2. A rapid increase in stress level can be seen in in-situ shear test results, in low shear displacements, up to reaching a maximum of τp (peak point) and afterwards reduction in shear stress with softening behavior.

Cohesion and shear strength levels also increase by increasing the depth. According to the plate load tests results, an increase in soil modules changes can be seen in different depths by depth increasing.

Large tendencies to increase in volume and dilation can be seen in under shear load cemented soils, after applying a primary compression on them. A brittle behavior with the occurrence of a certain peak can be seen in cemented samples. The significant increase in strength is directly related to the severe dilation rate, which can be seen in cemented samples results. The shear strength would be decreased, if this cement is broken during the particles’ displacements.

The results of downhole tests are shown in Figure 2. According to this figure, it has been explored that Vs,30 is about 600 m/s in moderate cemented soils while it is about 850 m/s in highly cemented soils. Because of the homogeneity and uniformity of sedimentary deposits, shear wave velocity is increasing due to the higher density of the layers and high level of cementation in both of the soil types. However, this increase is not significant at depths above 25 meters.

Conclusion

Based on the results, cementation level of the eastern coarse-grain-alluvium of Tehran is moderate to high and minerals used in cementation of this type of soil are generally carbonated and especially calcite.

Investigating the level of cementation of soil as well as the results of chemical analysis and in-situ tests, it can be found that the strength and deformation parameters of the soil are directly related to the degree of its cementation.

Based on the obtained results, the deformation modulus increases by about 25%, the cohesion by about 55% and the shear wave velocity by about 30% with increasing the degree of cementation (Table 1).

Increases of these parameters are directly related to depth. However, the cementation level does not significantly affect the internal friction angle of the soil.

Table 1. Average results of in-situ shear tests

| Deformation Modulus (MPa) | Peak Friction Angle (deg.) | Cohesion (kPa) |

USCS | Depth (m) |

Sample |

| 50-60 | 39 | 30-35 | GW-GM | 5 | Moderately Cemented Soil (M.C. Soil) |

| 75-85 | 41 | 50-60 | SP-SC | 10 | |

| 85-90 | 41 | 50-60 | GW-GC | 15 | |

| 95-105 | 41 | 50-60 | GW-GC | 20 | |

| 60-70 | 39 | 35-40 | GW-GM | 5 | Highly Cemented Soil (H.C. Soil) |

| 75-85 | 39 | 50-60 | GW-GC | 10 | |

| 110-120 | 42 | 65-75 | GW-GC | 15 | |

| 125-140 | 41 | 110-120 | GC | 20 |

| Page 1 from 1 |

© 2025 CC BY-NC 4.0 | Journal of Engineering Geology

Designed & Developed by : Yektaweb